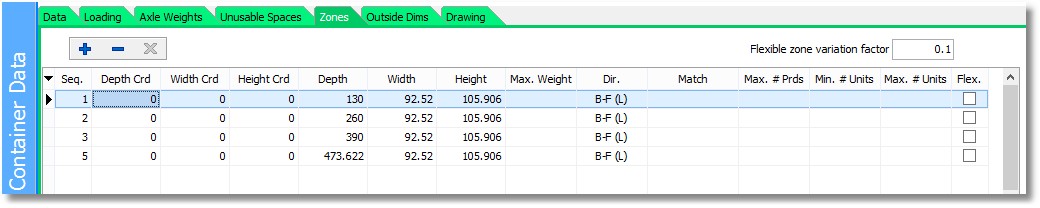

Container Details - Zones tab

Click on the main Containers tab, or use the F6 key.

Click on the Zones tab.

Zones are one the main new features of Cube-IQ 4. Use of Zones allows you to handle some very complex loading preferences, if set up properly. Please see later in this section for some examples.

On this tab, you can define different 'Zones' (called 'Load Spaces' in a previous release of Cube-IQ) inside the Container. Each Zone has a location (coordinates from back, left, bottom) and internal loadable dimensions. Zones can overlap. If the height co-ordinate of a Zone is greater than zero, its floor is assumed to support loaded units.

Each Zone can also have its own values for several other data fields:

•Sequence - the Zone with the lowest sequence number will be loaded first, and so on.

•Max. Weight - the weight capacity of the Zone

•Load direction - possible values are B-F (= Back-Front), F-B, L-R (= Left-Right) and R-L. The L/R between brackets indicates the alignment, which can be (L) for 'left in the Load direction' or (R) for 'right in the Load direction'. The starting corner for loading in a given Zone is shown as a small red dot in the graphics.

•Match - just like a Container, a Zone can have its own Matching Code, allowing you to let certain Products be loaded only in Zones that have the same Matching Code as the Product involved.

•Maximum number of different Products (for now, this value can only be blank = 'no limit', or 1 = 'single unit only')

•Minimum and maximum number of units

•Flexible - within certain limits, Cube-IQ will vary the length/height of the zone (depending on the main Load Direction of the Container) automatically , in order to find an optimal fill. The amount of variation is set in the Containers' Flexible Zone variation factor, also on this Container tab.

Zones with their own data gives the user a very flexible mechanism to set up some rather complex loading scenarios. Here are some examples:

(1) in the picture above, a rail car has been set up with doors in the middle of the right side. It will be first loaded from the 'back' (top right in the picture) towards the door, then from the front towards the door, and finally from the other wall to the door. Note that the Zones could have been made to overlap.

(2) if you want to load a Container with pallets only, except that boxes are allowed in any remaining space close to the door, you need two Zones. One for the whole Container, and one for a small space close to the door. The second Zone gets 'door' as Product matching code, and all boxes get 'door' as Container matching code. As a result the boxes are not allowed in the main Zone, only at the door. To avoid that the system puts a small number of boxes in the Container, you could give the 'Minimum # boxes' field a value, like 30.

(3) in Australia, drop deck trailers have separate weight limits for the 'high' space, and for the 'low' space. Two Zones with their own limits will do the trick.

Available, but still under development is a new field for Zones: 'Flexible'. A Zone can only be flexible if two of its three dimensions are the same as those of the container, and the third one is different. The third, different dimension will be used in a flexible manner by Cube-IQ, with a maximum variation of a percentage of the corresponding full container dimension. This percanteg can be set in the field 'Flexible zone variation factor', right above the Zone data grid.

In the example below, Cube-IQ will find an optimal length for the first Zone, between