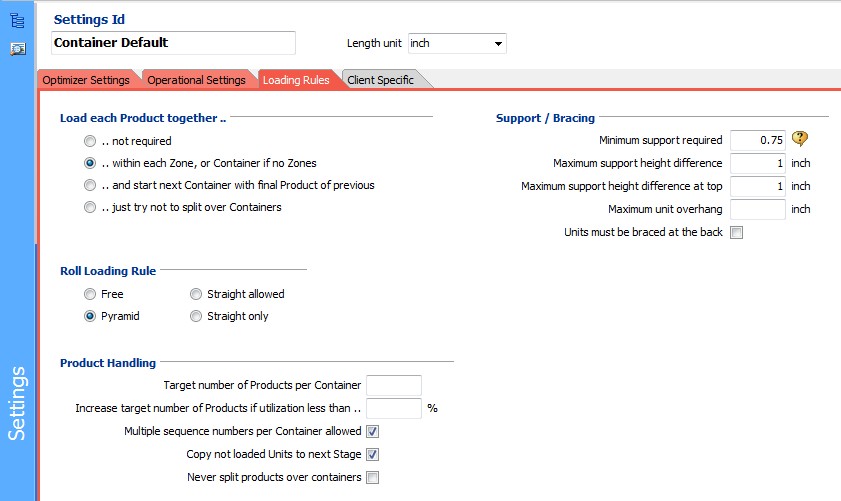

Settings - Loading Rules

Click on the main Settings tab, or press F7.

Then click on the Loading Settings tab.

Loading Rules concern rules on what is to be loaded and in which sequence or grouping.

Load each product together ..

.. not required - Products may get split during loading

.. within each Zone, or Container if no Zones - each Product will be loaded consecutively, that is, after loading the first one, all will be loaded (with possibly a leftover going into a later Container).

.. and start next Zone/Container with final Product of previous - Products will get loaded together, also when starting a next Zone, or even Container. This is typically only used in production environments, where Products need to get loaded as they become available.

.. just try not to split over Containers - this is not a hard rule. Cube-IQ will minimize the number of Products that have been to be split over Containers in multi-Container Loads. Note that Products may still end up getting split.

Product Handling

Target number of Products per Container - the optimization engine of Cube-IQ will Load no more different Products than this number in a single Container, as long as the volume utilization reaches at least the value of the next setting (see below). If this utilization cannot be reached, the system will try to load one more Product. This will continue until the target number is the original number plus three. From then on the system will simply optimize overall volume/weight without regard to how many different units are used. Note: Users should experiment with several values to find out what works best in their particular situation.

Increase target number of Products if utilization less than .. - the system will automatically keep increasing the target number of Products (previous Settings) until this utilization percentage can be reached.

Products with different sequence numbers can be mixed - if checked, the optimization can combine units with different sequence numbers in one Container. This setting is typically used in palletization or cartonization, where each sequence number represents a Customer or a drop, and units for different Customers cannot be mixed on one pallet or on one box.

Copy not loaded units to next stage - a setting for multi-stage loading, say, boxes on pallets and pallets onto a truck. If checked, not just the loaded pallets are made available for loading in Stage 2, but also all boxes that were not loaded in Stage 1.

Never split over Containers (unless quantity too big) - hard rule that each Product must be loaded within a single Container (unless really not possible due to total volume for the Product).

Roll loading rule

New to Cube-IQ5.1is that it can Load rolls on their (round) side. With this rule, you can set that loading of rolls can be done

•Free, which includes the possibility lean rolls against Container walls,

•in Pyramids only (where each roll is either on the floor, or saddle supported by two other rolls).

•Straight Allowed, which is the same as Free, but straight above another rolls is allowed,

•Straight Only, which effectively means that the rolls are treated as boxes.

Support

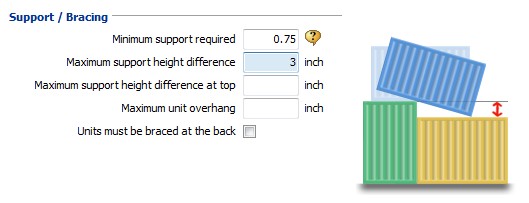

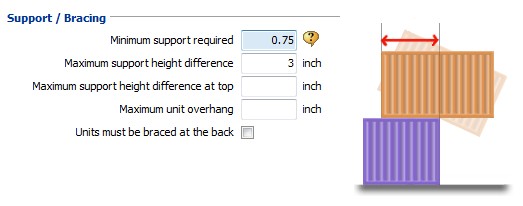

Minimum support required - to avoid 'floating' units support is needed for at least this factor's value of the length and the width of the unit. This is set with this value (as illustrated in the Settings window)

Maximum support height difference - Cube-IQ assumes that a unit may be supported by one that is slightly lower with its top than the unit is with its bottom level (absolute value, illustrated in the Settings window)