Settings - Operational

Click on the main Settings tab, or press F7.

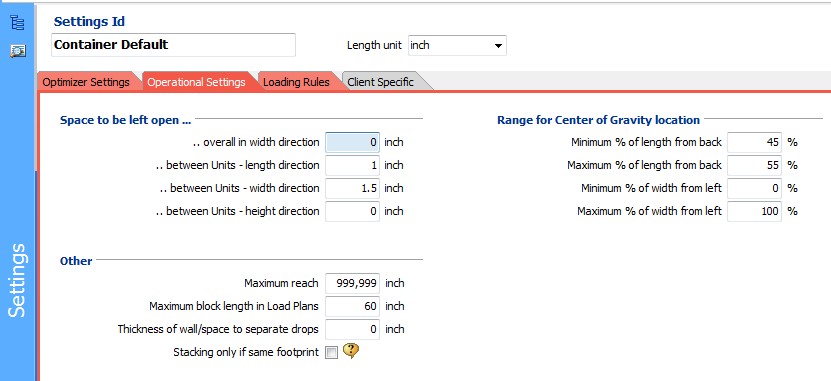

Then click on the Operational Settings tab.

The Operational Settings define rules on how the Container is to be loaded.

Space to be left open ...

.. overall in width direction - lets you define a certain amount of space that needs to be kept when loading, possibly to cater for data uncertainty, or for ease of loading. Note that this is an absolute value, not a percentage. Cube-IQ will leave this space one time in the width direction

.. between units - length/width/height direction - lets you define a certain amount of space that needs to be kept between each pair of loaded units, in the loading direction from back to front/left to right/bottom to top. Again that this is an absolute value.

Range for Centre of Gravity location

The Centre of Gravity data fields provide Settings on how the optimization should position the centre of gravity (automatically). Here you can set limits for back, front, left and right. These are percentages of the full dimensions. For example, if you want the center of gravity in the length direction to be within 45% and 55% of the Container length (that is, +/- 5% from the length centre), enter a 45 for the 'back' limit and a 55 for the 'front' limit.

The positioning of the center of gravity will only take place for directions (length or width) where two values have been entered.

Other

Maximum reach - sets how far 'reach' back into the Container is possible, for example after finishing all boxes of a given sequence number, and starting the next sequence number.

Maximum block length in Load Plans - is used to determine the maximum depth dimension of blocks of units, which will make up the loading sequence. So, this is the length-wise step size of the Load Plan. If you give this Setting a large value (say 1,000,000), blocks may be as long as the whole container. This makes for much smaller Load Plans (far less blocks), but is not easy to interpret as loading instructions.

Thickness of wall to separate drops - If a positive value is present in this field, the system will not mix units with different sequence numbers (that is, for different drops), but keep them separated by an invisible wall that has this value as its width. If mixing units with different sequence numbers is ok, you can leave this field blank, or use a value 0.

Stacking only if same footprint - If checked, Cube-IQ will only stack a unit on top of another unit, if both have exactly the same foot print. Rules like this are common when loading paper rolls, or pallets that have slots.