Load - Other Data

Next to the Loads tab for the results are two more tabs on Load Setup. The first additional tab is for Loading Rules, the second for additional Load Data fields.

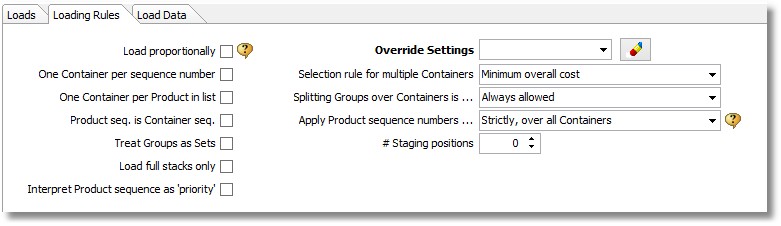

This is the Loading Rules tab of Load Setup:

For many of the rules set here you can define default values for newly created Loads on the main Options tab.

Check 'Load Proportionally' if the quantities in the Load List indicate in which proportion the various Products are to be loaded. If, for example, you do not know the exact numbers of Products that will fill a Container, but only want to set relative numbers, start by making only one Container available. If you would then give three Products quantities 1, 2, and 4, Cube-IQ will Load maximum numbers, roughly proportional to 1:2:4, for example, 100, 195 and 408.

Check 'One Container per sequence number' if you want the sequence column in the Load List to indicate into which Container in the list certain Products should go. So, Products with sequence 2 will go into the Container that is second in the list, for example.

Check 'One Container per Product in list' if you want to find out for many Products how many of each (on their own) fit in one Container. We see this typically being used in Palletizing. So, if you have 200 Products in the list, you will get 200 loaded pallets, one for each Product.

Check 'Product seq. is Container sequence' if you want the sequence column in the Load List to indicate into which loaded Container certain Products should go. (Products with sequence 2 will go into the second Container, for example.) This option is used in some cases where Customers of Cube-IQ clients specify the whole Load allocation, and Cube-IQ is used only to check those Loads.

Check 'Treat Groups as Sets' if you have split the Products in the list into groups (by giving each group a unique (Integer) number, where each group represents a set. An example is 'one table and four chairs'. If such a group/set gets loaded, loading will always take place proportionally. So, if you ask for five sets to be loaded (5 tables and 20 chairs), and this does not fit, the system may cut the quantities to 4 tables and 16 chairs. It will not do 5 tables and 13 chairs.

Check 'Load full stacks only' if you want the software to only load bundles of a Product that have as many units in the height as the Product's maximum stack quantity..

Interpret Product sequence as 'priority' loads the Container in Product sequence, but on the assumption that the actual loading may take place differently. So, the sequence is more of priority, than one of operational necessity. It also means that settings like 'Maximum Reach' do not kick in, and that the sequence presented to the user may not adhere to the Product sequence.

You can select here a set of Settings that is to be used to override the Settings of the selected Containers. This is useful if you have set up special Settings with different (possibly relaxed) loading rules.

The Selection rule for multiple Containers sets in which order different Containers are to be used by the optimization, when doing a Load involving multiple Container types. The choices are

•Best fit sequence - in each step, all Containers are loaded, and the one with the highest utilization is selected,

•Largest first - in each step the largest available Container is used, except in the last step where the best fitting Container is used.

•Minimum overall cost - the system will attempt to determine which set of Containers will lead to the lowest overall Container cost. If no costs are provided (in Container Details), the system will calculate its own 'costs', which are designed to minimize the number of Containers used, and given the number used, the overall volume used.

•One Container only - a single Container will be loaded, and if more than one Container is required, no Load will be produced at all. (This particular rule is only used in some cartonization applications.)

•Largest reaching minimum fill first - repeatedly the system will Load the largest Container that can be filled for at least its minimum fill percentage.

•Sequenced reaching minimum fill first - repeatedly the system will Load the Container with the lowest sequence number that can be filled for at least its minimum fill percentage.

•Minimum overall cost + Largest First - both rules are applied in two consecutive, separate runs of the optimizer, and the best results are presented to the user. This rule is based on the experience of some users who found that one rule works best on some of their loads, and the other rule best on other loads.

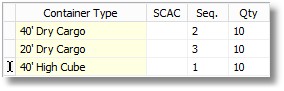

Note that the Container Selection rule is not used when different (hard) sequence numbers have been entered for the available Container types, as shown here:

Splitting groups over Containers is ...

This rule selects what the optimization is allowed to do with Products that share a 'group' number. The Options for splitting of groups over loaded Containers are:

•Always allowed - in this case, groups are only used to keep Products together within a loaded Container, even when a subsequent Container may also another group of these Products.

•Allowed if it avoids an extra Container - group splitting is not done, unless it saves a whole Container.

•Allowed only when too large for one Container - groups are not split, except when the whole group would not fit into a single Container.

•Never allowed - the results may be that groups are not loaded when too large or too heavy for one Container.

The 'Apply Product sequence number ..' rule gives you a choice of two Options:

(1) 'Strictly, over all Containers', which leads to the Product sequence numbers being applied 'hard' over all Containers. The system start loading the lowest sequence number on the first Container, and continues with this sequence number until they are all done. So, no Product with a certain sequence number will be loaded until all Products with lower sequence numbers are in some loaded Container.

(2) 'Strictly per Container, skipping allowed', as used in for example cartonization. The Product sequence gets applied for each individual Container (typically a pallet or carton). This means for example that the first carton may contain Products with sequence numbers 2, 3 and 4, the second Container may hold 1, 2, 5, and the third Container 4, 5, and 6.

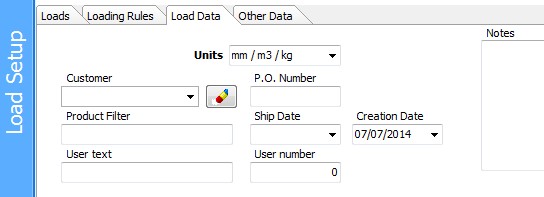

And the third tab is for some other Load Data fields:

If a Customer has been selected (click the drop down arrow for a list, and the '-' button to clear), its data will be used when printing a Loading Manifest.

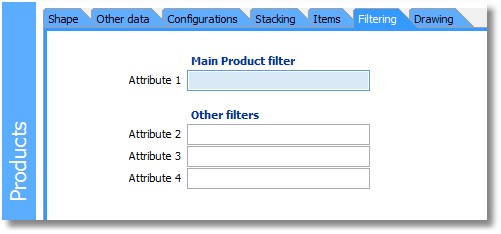

The Product Filter is a very important tool to restrict which Products are currently visible. If this field is given a value, only Products with the same value or with no value in their Main Product Filter field will be visible. You database may contain Products for Customers named Jones, Smith and Johnson Brothers. If Product Filter is set to 'Johnson Brothers' only the Product for that client will be visible in the system (as long as you are working on this Load). This is what the field looks like in the Product Data window:

The Notes are printed on the Load Plan and the Manifest, if on the FILE tab you selected 'Print Notes from Load Data'.

'P.O Number ' is in fact a user-definable string of information, not used directly by Cube-IQ but displayed and printed in some reports. You can use Tools/Translation to change the text 'P.O. Number' into something else. The user also has 'User number' and 'User text' available for any purpose, that can be set by translating the captions.

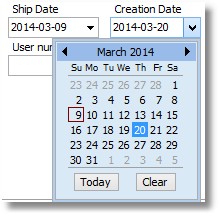

'Ship Date ' a date field which can be used for example for the expected shipping date. This field is used only for display and printing. Click the down arrow for a Date Picker as shown below.

'Creation Date ' is the date when the Load was last optimized.

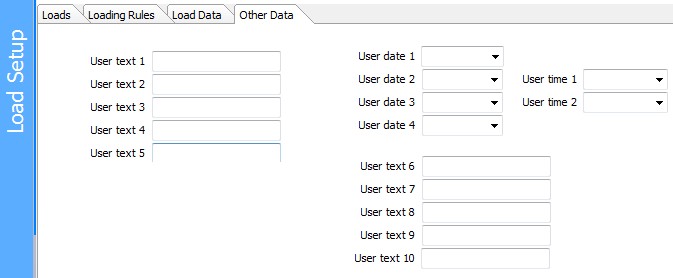

Finally, in Options, General tab, you can make a fourth tab visible for access to a series of User Definable fields. These can be used for various purposes.