Container Details - Loading Tab

Click on the main Containers tab, or use the F6 key.

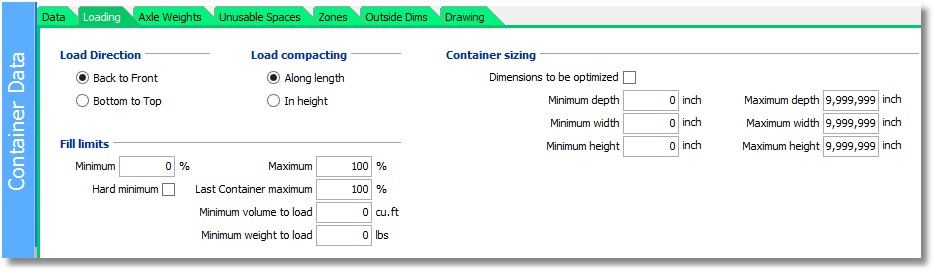

Click on the Loading tab . On this tab, you can enter values for several data fields of the 'Container'.

Load Direction - a choice between 'Back to Front' and 'Bottom to Top'. The first option is typically used for shipping containers and trucks, and the latter for pallets, crates and boxes.

(Note that the normal loading sequence in a truck is called 'back to front' in Cube-IQ. So, what Cube-IQ calls the 'back' is typically at the front of a truck.)

Load compacting - if 'Along length' is checked, partial Loads will be loaded as far back in the Container as possible. 'In height' will let the Load engine spread partial Loads over the Container floor. Below, the first picture shows 'Use Back first', and the second 'Use Floor first'.

Fill percentage - If 'Hard minimum ' is checked, no Container will be loaded below the minimum fill percentage. (Note that this may leave some Products unloaded.) If the minimum fill percentage is not 'hard', Containers may be loaded below that value, but a warning will be given in Load Setup by showing the fill percentage in red and bold. You can also set a maximum fill percentage, and even use a higher fill percentage for the very last Container in a multi-Container Load. This may avoid one extra Container with some very low fill.

On the main Options Tab, you can set Cube-IQ to show 'Container sizing'. This allows the user to set minimum and maximum dimensions for the Container(s) to be used. Given the Load, the system will then propose internal Container dimensions that would fit that Load optimally. It may be used when the Container will be some custom-made box or crate. This is typical for the loading of art, or custom window and doors.

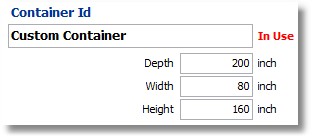

In this example, the original full dimensions of the Container are set as follows:

The sizing data is

Note that the original size is set to define the shape of the crate. It is to be long and narrow. It is important to give the system ample time to find the best Containers, which is done by giving the Optimizer Settings field 'Maximum run time' a value of at least 30 seconds, and the field 'Maximum number of non-improving iterations' a value of at least 1000 (2500 preferred).

After optimizing a Load, and even after manual editing of the Load, the proposed custom dimensions are shown on the Results tab of Load Setup:

In this case, Cube-IQ proposes three custom crates, of dimensions 160x40x160 (shown), 120x60x120, and 180x40x120.